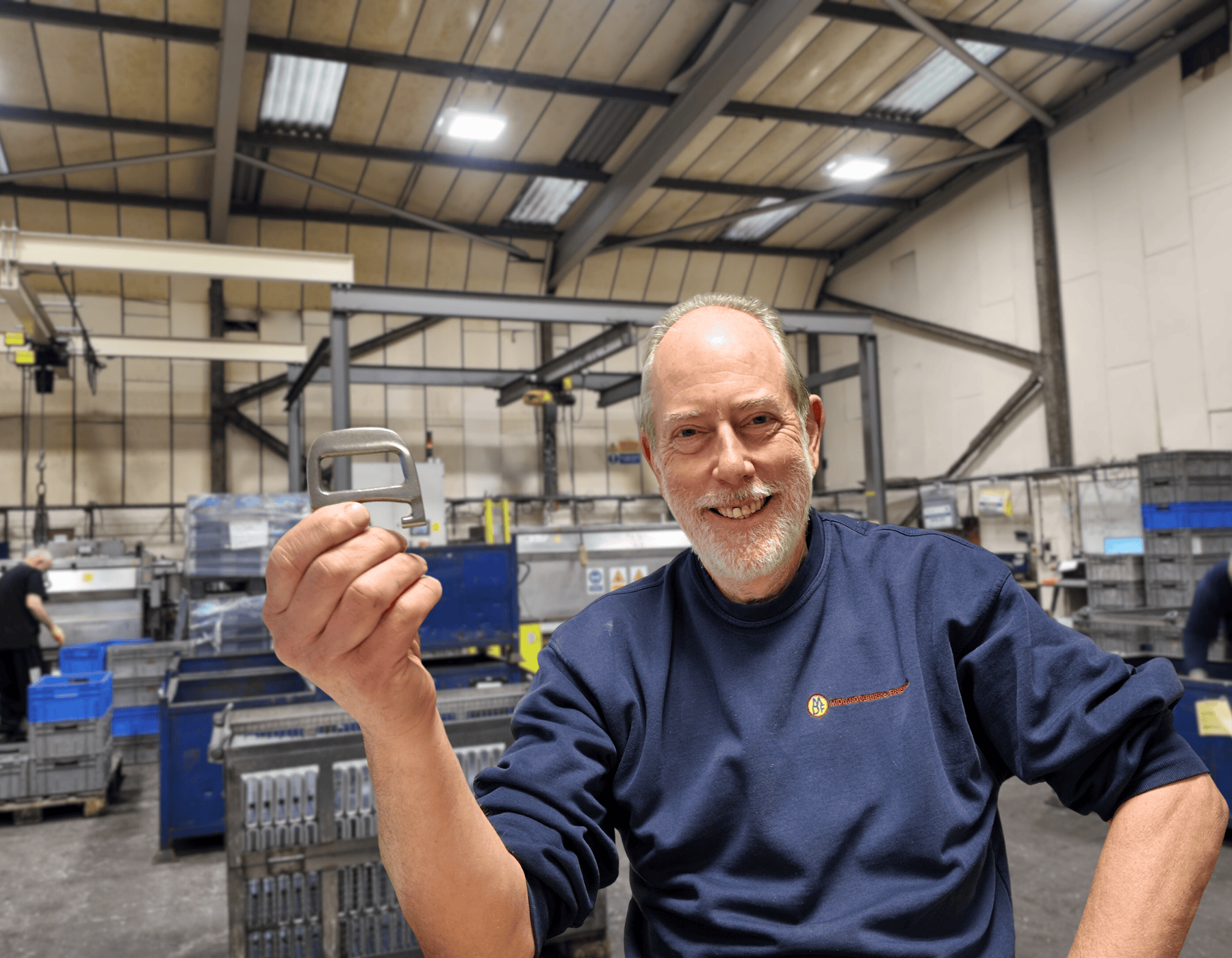

Global deburring boom puts Black Country surface finishing in the spotlight

Global forecasts showing the deburring machine market rising from USD 1.1 billion in 2025 to USD 1.8 billion by 2035 may look like abstract numbers, however for Midland Deburr & Finish in Lye they simply confirm a reality already felt on the ground. Managing director Chris Arrowsmith says the shift is unmistakable: finishing has moved from a background task to a strategic capability for manufacturers under pressure to deliver cleaner, safer and more consistent edges at ever tighter tolerances. “Those figures absolutely track with what we’re seeing from aerospace, automotive and precision engineering customers in the Midlands,” he explains. “The tolerance stack is tightening, audits are getting tougher and everyone wants consistent edge quality at volume. You can’t do that with a man, a file and a bucket any more – you need serious finishing machinery.”

The global outlook shows vibratory deburring remaining the dominant technology, taking roughly 26.8% of the market, while automatic systems account for more than half of installed equipment. For Midland Deburr, that reflects daily reality. Vibratory bowls and tubs still underpin most volume finishing in the UK because they deliver repeatable results across huge batch sizes while preparing surfaces for coating, plating or assembly. As Arrowsmith notes, vibratory finishing remains the backbone of the business precisely because of that combination of productivity and consistency.

It allows thousands of components to be processed in a single cycle, and with the right media and chemistry the results are extremely stable. Customers who once treated edge finishing as an afterthought are now engaging with process development far earlier, asking for guidance on media selection, cycle times and finish validation as part of new product introduction. “When a Tier 1 or Tier 2 installs a new machining cell, the finishing conversation now happens on day one,” Arrowsmith says. “Ten years ago, it usually didn’t happen until someone started failing inspections.”

This shift has changed the role Midland Deburr & Finish plays for many clients. Rather than simply processing parts to a standard finish, the business increasingly acts as a partner in process engineering, helping customers optimise surface conditioning, choose the right media, understand Ra requirements and balance cycle times with cost per part. The complexity of modern components and the scarcity of skilled manual deburrers have created a gap that machine-based finishing now fills.

Global demand is rising because machining is becoming more advanced while labour availability is tightening. Components manufactured with multi-axis CNC equipment, intricate geometries and lightweight materials all need consistent burr removal, and the margin for manual variation has all but vanished.

Automatic and robotic deburring systems, which now hold the majority share of global installations, reflect another trend Arrowsmith recognises: the push for unmanned operation, tighter process control and integrated data capture. While SMEs may not always install fully automated cells, they feel the same pressure from customers who increasingly expect traceability and consistency built into every step of production.

According to Arrowsmith, the real bottleneck is no longer hardware availability; its skills. “The technology is there – you can buy fully automated cells with robots, in-line deburring and data logging. The bigger question is: who’s going to specify it, program it and keep it running? The real constraint isn’t the machines; it’s the knowledge.”

This is why Midland Deburr has chosen to specialise in the best equipment and crucially in the expertise that underpins process reliability. The company routinely proves out finishing routes for customers before they commit to capital spend, trains production teams on what a compliant edge condition looks like, and helps build finishing considerations into NPI rather than leaving them until the end. Arrowsmith describes this approach as “taking the complexity off their plate” so clients do not need to become deburring specialists themselves.

The UK market is forecast to grow steadily at around 4.8% through 2035, driven by aerospace, defence, medical devices and precision engineering—sectors in which surface integrity is critical. That positions the Black Country well, as Midland Deburr services customers across exactly these fields.

“From our site in Lye, we’re right in the middle of one of Europe’s most diverse manufacturing regions,” says Arrowsmith. “We’re finishing parts that end up in jet engines, off-highway vehicles, medical equipment and critical fasteners. The global numbers tell you demand is rising; the view from our loading bay tells you where that growth is physically happening.”

Sustainability is also reshaping finishing practices. Customers now ask detailed questions about media life, waste management and chemical use, driven by ESG requirements and regulatory scrutiny. Midland Deburr has responded with investments in longer-life media, improved separation systems and more advanced effluent treatment. As Arrowsmith notes, being able to meet a specification is no longer enough; manufacturers increasingly expect a finishing partner to help them meet environmental obligations as well as quality ones.

Ultimately, he believes the next decade will reward firms that anticipate rather than react. “If the world is heading towards more automation, more traceability and higher finishing standards, then we have two choices,” he says. “Either we wait until customers start failing audits, or we get ahead of the curve, invest in the right machines and processes, and help them avoid those problems altogether.

At Midland Deburr & Finish, we’ve chosen the second option. We’re not in the business of selling machines – we’re in the business of selling confidence in the surface. And the global data only reinforces how important that will be for years to come.”

Quick Contact Form