Critical Parameters in Metal Degreasing

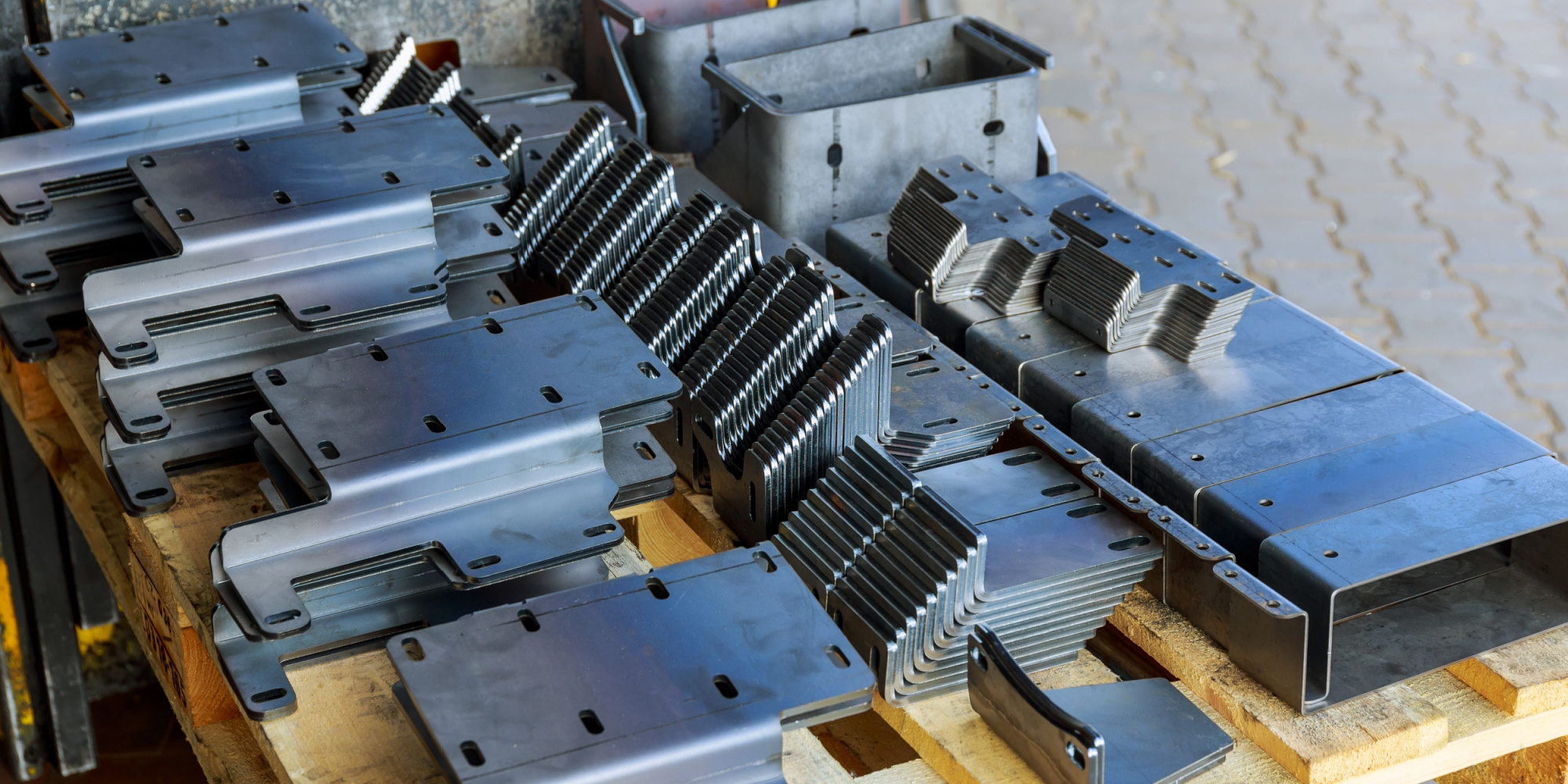

In the intricate process of surface pre-treatment, particularly in the metal degreasing phase, it is crucial to consider various parameters to guarantee optimal and uniform outcomes. For twenty-five years, Midland Deburr & Finish have positioned themselve as market leaders in science and application of metal degreasing and metal finishing.

These are the factors encompassing the correct consideration to metal degreasing in surface pre-treatment:

Temperature Has To Be Right: The temperature of the degreasing solution stands as a pivotal parameter influencing cleaning efficiency. While elevated temperatures can enhance cleaning effectiveness, they must be carefully calibrated to avoid any adverse effects on the material being cleaned. The optimal temperature range is contingent on the specific degreasing agent in use and the composition of the material.

Concentration Of Solution: The concentration of the metal degreasing solution plays a critical role in its ability to remove contaminants effectively. The optimal concentration range is subject to variables such as the specific degreasing agent employed and the nature and extent of contaminants present.

Contact Time With Parts: The duration of contact between the degreasing solution and the material being cleaned is paramount for achieving thorough cleaning. The optimal contact time varies based on the degreasing agent and the specific contaminants being addressed.

Agitation Levels: Introducing agitation to the degreasing solution can significantly enhance cleaning efficiency by promoting increased contact between the solution and the material. The ideal method and intensity of agitation hinge on the specific degreasing agent and the characteristics of the contaminants.

Rinse Water Quality Considered: Adequate rinsing is essential to eliminate all remnants of the degreasing solution and prevent contamination in subsequent processing steps. Optimising the quality of rinse water, considering factors like purity and temperature, is imperative for effective rinsing.

Equipment Maintenance Crucial: Ensuring the proper upkeep of degreasing equipment is vital for consistent cleaning performance and to prevent equipment failures. Regular cleaning, inspection, and timely replacement of worn or damaged parts contribute to the overall reliability and efficiency of the degreasing process.

Metal degreasing continues to be an important process in the finishing of metal components so to ensure your parts get the right metal degreasing finish, speak to our experts.

Quick Contact Form