"Its time to return to growth", says metal finishing leader, amidst renewed confidence in manufacturing sector

Midland Deburr & Finish Ltd in Lye, West Midlands, the leading subcontract specialist in metal finishing, is reporting a sense of improved confidence in the sector for subcontract deburring services. The prospect of renewed order volumes in deburring is linked to this discernible boost in customer confidence. While multifaceted, this uplift in sentiment is understood to be influenced by several factors, potentially including positive news surrounding international trade discussions and tariff resolutions, such as recent updates on US/UK trade relationships.

Established in 1999, Midland Deburr & Finish has built a reputation as a cost-effective outsourcing solution for companies looking to delegate "Dirty processes," including metal degreasing, component degreasing, deburring, mechanical finishing, and general surface improvement. Their services encompass a comprehensive range, including metal degreasing, solvent degreasing, vapour degreasing, vibro deburring, barrelling, and casting impregnation. The company serves a diverse customer base, from large corporations to small businesses, across sectors such as automotive, aerospace, and Formula One.

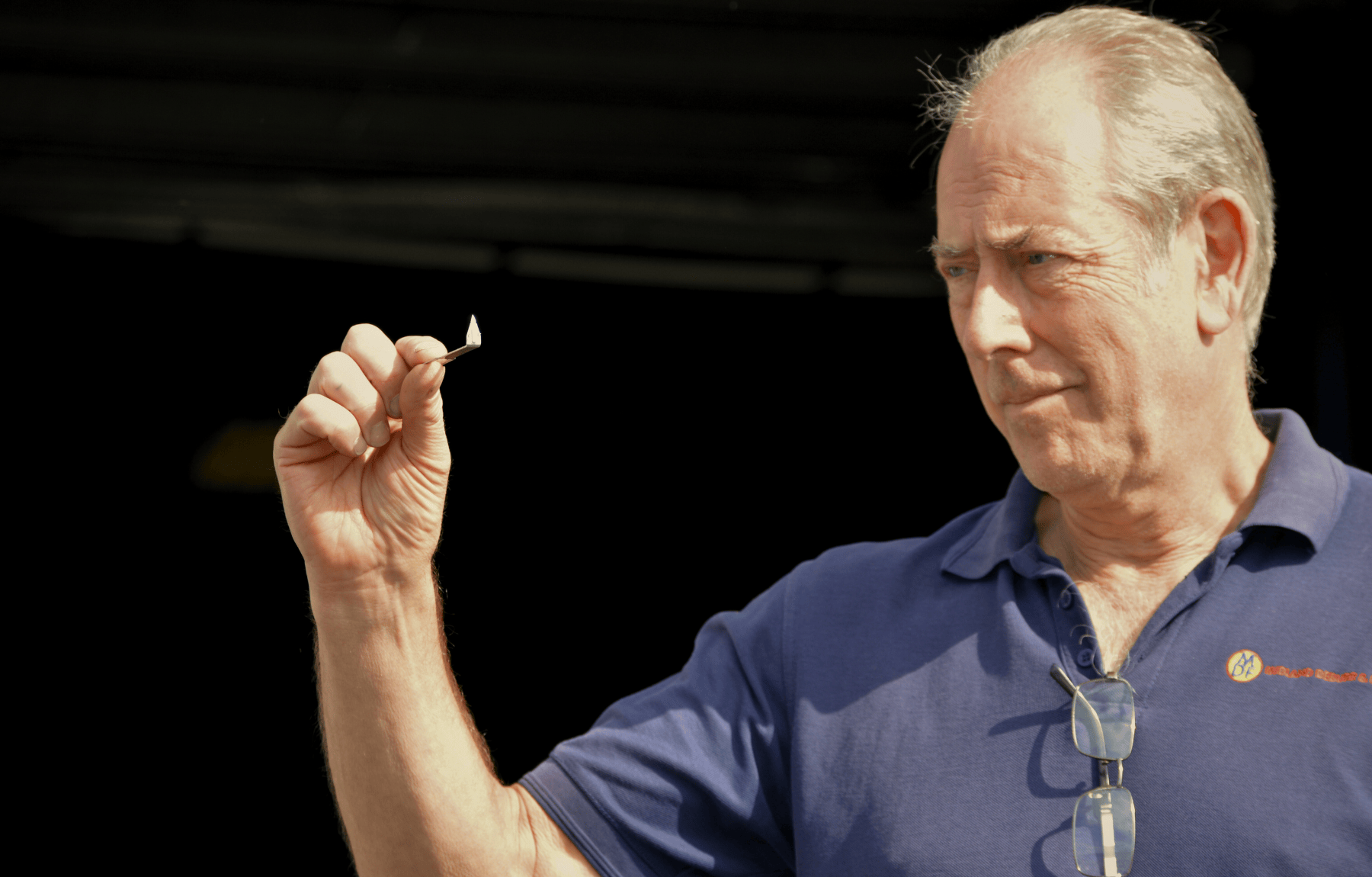

This renewed determination from manufacturers to push forward is a welcome development, according to Chris Arrowsmith, Managing Director of Midland Deburr & Finish. Commenting on the trend, Arrowsmith noted, "It's incredibly encouraging to see this renewed vigour in the manufacturing sector. There's a definite sense of optimism returning, the key is to turn this into action and fire up the UK manufacturing economy once more."

Arrowsmith highlighted that this environment makes the case for subcontracting services like Midland Deburr & Finish even stronger. Drawing on years of expertise in providing surface improvement as specialists, Midland Deburr & Finish understands the complexities involved in processes like vibratory tumbling, a common method for deburring, descaling, edge-breaking, and polishing.

"Manufacturers may instinctively look at purchasing their own vibratory finishing equipment at some stage, believing it's a cost-effective long-term investment," Arrowsmith explained. "However, the reality is achieving a consistent, high-quality finish requires far more than just owning a machine. It demands a deep understanding of media selection, process parameters, and batch optimisation," factors that can significantly impact efficiency.

He elaborated on the challenges faced by companies attempting in-house finishing: "Often, businesses underestimate the true complexity. They might assume you can simply load parts and media and achieve the perfect finish straight away. In reality, it's a highly nuanced process requiring precise control over variables from media-to-part ratio to cycle time and compound selection." Without this expertise, companies can encounter "inconsistent results, high scrap rates, and wasted time spent on trial-and-error adjustments".

For companies experiencing increased demand due to renewed confidence, outsourcing becomes a strategically smarter choice. Subcontracting allows access to specialist knowledge without the need for years of process refinement or significant capital expenditure on machines. "A specialist subcontractor like us has optimised machine settings, proven media formulations, and stringent process controls already in place," Arrowsmith stated. "This ensures each batch receives a consistent, repeatable finish without the risk of process drift."

Midland Deburr & Finish offers a diverse range of vibro and barrel mass finishing services tailored to remove burrs, achieve uniform finishes, create precise radii, polish, and remove scale and rust, including specific finishes for pre-plate/paint preparation. Their capability to handle complex part geometries and varying batch sizes, from 1 to 1000s, further underscores the benefits of their specialised approach.

Arrowsmith concluded, "The decision for manufacturers should be about process control, efficiency, and long-term cost-effectiveness. By partnering with an experienced subcontractor, businesses can achieve superior results without the risks and complexities associated with managing these processes in-house. The increase in orders reflects this understanding, and we're ready to support our customers as confidence returns to the market."

As a privately owned company, Midland Deburr & Finish Ltd prides itself on offering a personal and friendly service, dedicated to looking after their customers’ solvent degreasing, vapour degreasing, and deburring needs. Their commitment to quality and investment in process capacity positions them as a trusted partner during this period of positive market movement.

Quick Contact Form