Re-industrialising the Midlands: Why Precision Surface Finishing Deserves a Seat at the Table

As the government steps up its agenda to “level up” the UK economy and revitalise domestic manufacturing, the spotlight is often on big-name OEMs, new innovation hubs, and futuristic gigafactories. But beneath these visible efforts lies a network of unsung heroes – the SMEs that keep the wheels of industry turning. One such company is Midland Deburr & Finish Ltd, based in Lye, Stourbridge.

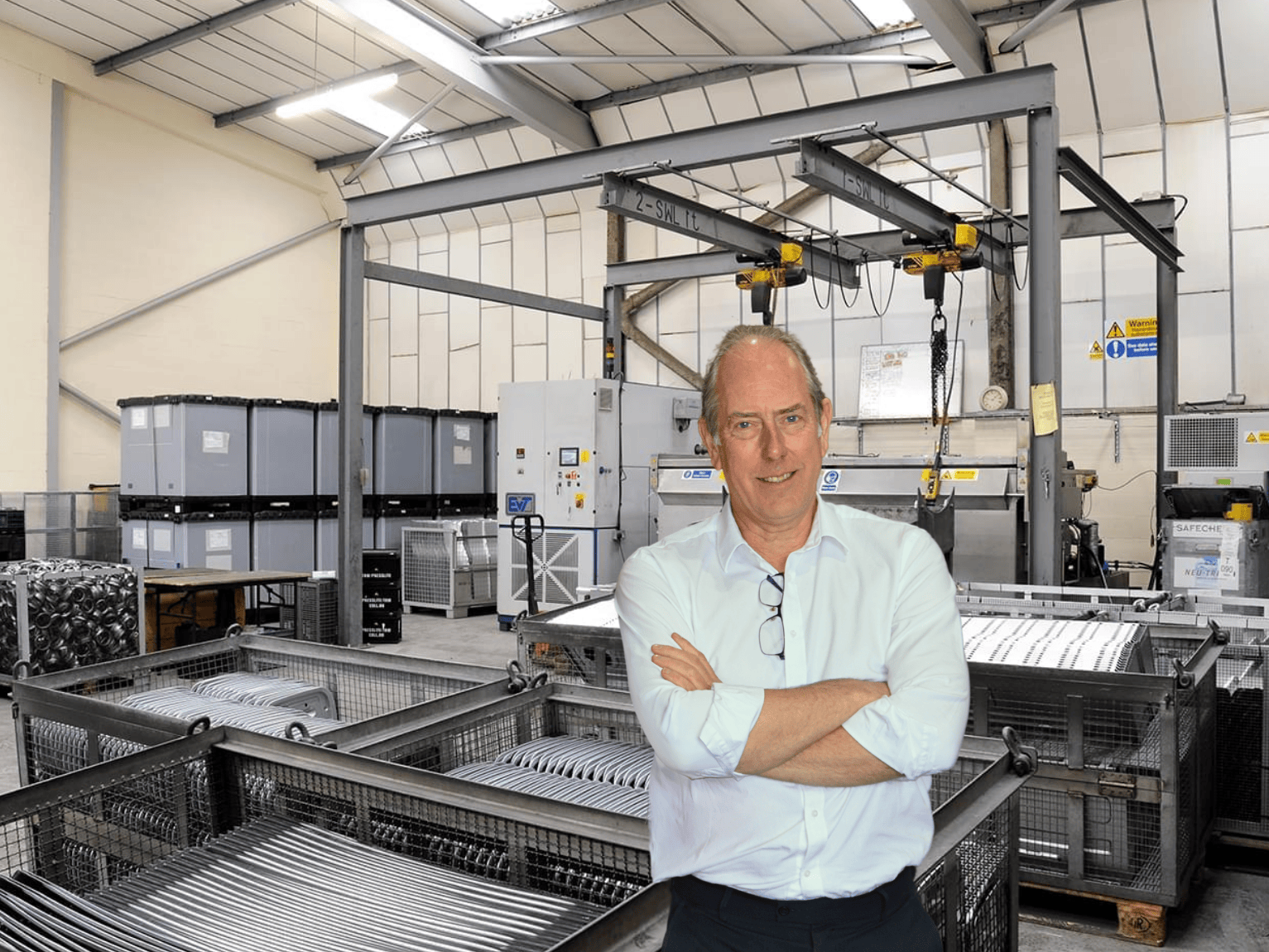

From its West Midlands base, Midland Deburr provides subcontract vibratory deburring services to high-spec industries including aerospace, defence, medical, and energy. It’s a critical process that ensures components are free of burrs, sharp edges, and imperfections before moving to coating, assembly, or installation. And as Managing Director Chris Arrowsmith explains, it’s a discipline that deserves more attention.

"There’s a misconception that advanced manufacturing is all about automation and AI," says Arrowsmith. "But without accurate, burr-free parts, even the smartest systems can falter. What we do here might not be glamorous, but it’s absolutely foundational."

As traditional Midlands industry reinvents itself for modern sectors like electric vehicles, nuclear, and med-tech, demand is growing for components that meet ever tighter tolerances. And with supply chain resilience high on the agenda, more OEMs are turning to domestic partners to handle precision finishing work.

"We’re seeing a resurgence in demand for UK-based subcontract services," says Arrowsmith. "There’s a renewed appreciation for quality, consistency, and fast turnaround – and that’s where SMEs like ours can shine."

But he warns that without strategic support, some of these capabilities risk being lost. "Metal Finishing is the final step in ensuring safety, performance, and longevity. If we want to reindustrialise Britain, we have to support every link in the chain."

Midland Deburr has invested in training, automation, and quality control systems to keep pace with rising expectations. Their staff work to microscopic tolerances, often on parts destined for life-saving or mission-critical roles.

"This is hands-on precision work. We’re inspecting every part, removing every flaw, and making sure our customers get something they can trust. That’s the value we bring."

He believes regional manufacturing clusters like the West Midlands can lead the national revival – but only if SMEs are seen as strategic assets, not just service providers. "If policymakers want real levelling up, they need to think local and think long-term. Give us the tools, the skills pipeline, and the recognition we need – and we’ll deliver."

Quick Contact Form