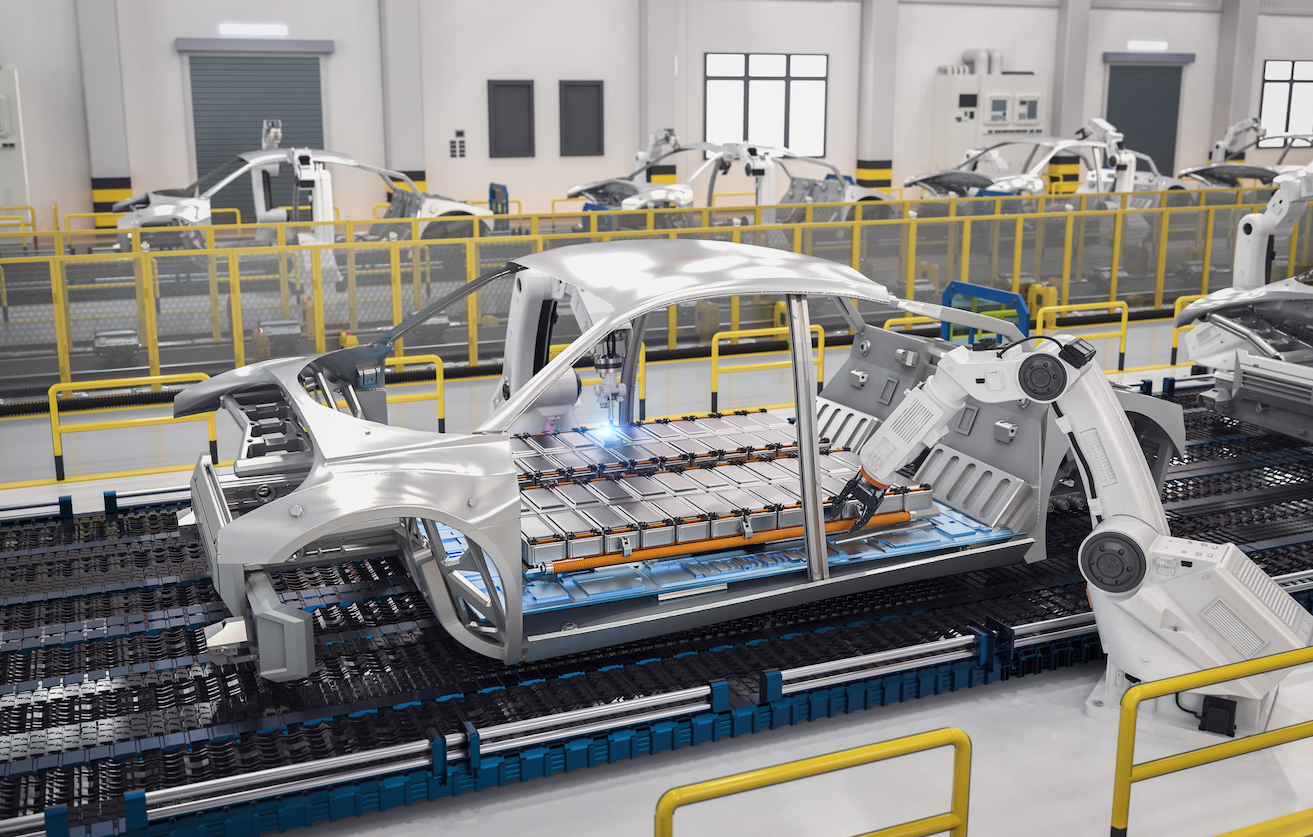

Midland Deburr & Finish Sees Surge in Metal Degreasing Demand Amid Booming UK BEV Sector

As UK battery electric vehicle (BEV) manufacturing accelerates ahead of global forecasts, Lye-based Midland Deburr & Finish is experiencing a significant uptick in demand for its advanced metal degreasing services—particularly from battery and component manufacturers.

The company, a specialist in solvent and vapour degreasing, is helping local manufacturers capitalise on efficiency gains and cleaner component finishes, aligning with the recent rise in UK Manufacturing PMI output.

“With BEV production scaling and component cleanliness under increasing scrutiny, our degreasing services have never been more essential,” said Chris Arrowsmith, Managing Director of Midland Deburr & Finish. “We’re seeing a growing number of enquiries from firms in the battery supply chain that need consistent, high-quality surface cleaning—especially for parts going into high-voltage assemblies.”

The business attributes much of its current growth to its ability to support the stringent technical requirements of battery components. Vapour degreasing, in particular, is seen as a key enabler for achieving the flawless, contaminant-free surfaces demanded by electric vehicle applications.

“Battery components—whether enclosures, terminals or connectors—must be absolutely free of oils, machining residues, or microscopic debris,” Arrowsmith explained. “Vapour and solvent degreasing give our clients the reliability they need, without risking watermarks or corrosion from traditional aqueous processes. It’s a major contributor to quality and efficiency.”

The company's ISO 9001 and ISO 14001 certifications underline its commitment to quality and environmental responsibility. Using environmentally compliant solvents and precision filtration systems down to 100 microns, Midland Deburr & Finish ensures meticulous cleanliness at scale, serving both high- and low-volume batch sizes.

The timing couldn’t be better. According to the latest Advanced Propulsion Centre (APC) demand report, the UK is on track to produce around 1 million battery electric vehicles per year by 2035, with strong mid-term growth across component demand. While hybrid vehicles will also play a role, battery systems remain central to long-term transition plans.

“In the context of reshoring and localising battery supply chains, we’re proud to be a Midlands-based partner offering manufacturers not only a technical edge, but fast, flexible service,” said Arrowsmith. “Turnaround speed matters more than ever—we’re set up to support next-day or even same-day degreasing. That’s a real advantage in today’s high-pressure manufacturing environment.”

Midland Deburr & Finish also provides clients with free consultancy to optimise their degreasing workflow, as well as professional packaging solutions to streamline logistics and minimise downtime.

With recent investments in automated vapour degreasing machinery, the firm is now capable of delivering repeatable, high-precision cleaning for every component, every time.

“We remove what you don’t want, so your products can perform exactly as designed. That’s true for aerospace, medical and now increasingly—battery systems. As BEV production ramps up, we’re ready to support it" Arrowsmith added.

Quick Contact Form