Driving Improvements in Metal Finishings in Automotive Cleaning with Ultrasonic Technology

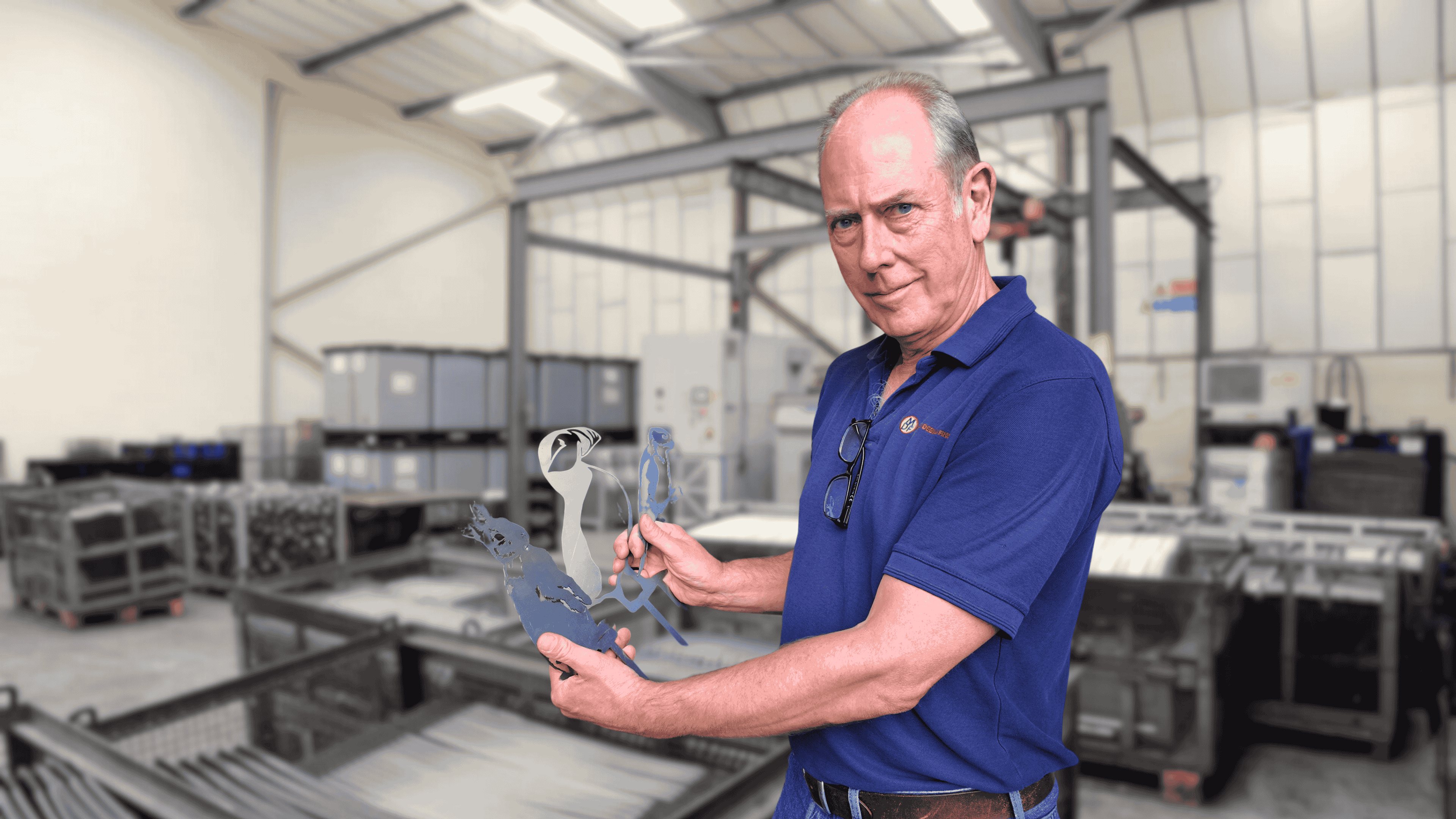

Lye-based specialist Midland Deburr & Finish is championing the use of ultrasonic cleaning in the automotive industry, highlighting its effectiveness, environmental benefits and potential to save manufacturers both time and money.

Ultrasonic cleaning is a process that uses high-frequency sound waves to agitate liquid. The energy creates microscopic bubbles that collapse with force, producing a scrubbing action capable of removing dirt, grease and carbon build-up from even the most complex components.

“It’s an incredibly precise yet powerful process,” said Chris Arrowsmith, Managing Director of Midland Deburr & Finish. “Because the bubbles are so small, they can access hard-to-reach areas that traditional cleaning methods often miss. For delicate parts, such as injectors or turbochargers, ultrasonic cleaning is also much gentler than abrasive or chemical-heavy techniques.”

Traditional cleaning methods in automotive engineering, such as solvent cleaning or vapour degreasing, have long been the norm. But both bring challenges. Solvent cleaning typically uses harsh chemicals like methylene chloride or trichloroethylene—effective but harmful to workers and the environment. Vapour degreasing, meanwhile, can achieve strong results but is costly and requires specialist equipment.

“Manufacturers are under pressure to find solutions that are not only technically effective, but safer and more sustainable,” said Arrowsmith. “Ultrasonic cleaning ticks all those boxes—it eliminates the need for aggressive chemicals and delivers a faster, more consistent clean.”

Midland Deburr & Finish is seeing growing demand from automotive customers seeking to overhaul engine components, gearboxes, injectors and radiators with ultrasonic technology. Applications range from degreasing cylinder heads and pumps to removing burned oils from turbochargers and cleaning transmission systems.

One of the standout advantages, according to Arrowsmith, is the speed of the process:

“Cleaning diesel injectors, for example, can take as little as ten to fifteen minutes with ultrasonic equipment. For garages, repair shops and manufacturers alike, that time saving translates directly into higher productivity and lower operating costs.”

A cleaner, greener future

The environmental impact of cleaning methods is also increasingly under scrutiny. Ultrasonic cleaning requires only water and a mild detergent, avoiding the health and waste management risks associated with solvents.

“Automotive businesses are rightly focused on sustainability and worker safety,” said Arrowsmith. “Ultrasonic cleaning supports both. It’s an efficient, non-toxic process that delivers high-quality results without compromise.”

Key benefits of ultrasonic cleaning for automotive components

-

More effective at removing dirt, grease and carbon deposits

-

Gentle enough for delicate components

-

Eliminates the need for harsh chemicals

-

Reaches inaccessible areas with ease

-

Suitable for a wide range of automotive parts

-

Faster than traditional cleaning methods

As the industry evolves, Midland Deburr & Finish believes ultrasonic cleaning will increasingly replace solvent-based methods.

“This is about future-proofing automotive cleaning,” Arrowsmith concluded. “By adopting ultrasonic technology, companies can achieve better results, protect their workforce, and reduce environmental impact—all while saving time and money.”

Quick Contact Form