Midland Deburr & Finish Joins Calls for Government Investment in Skills and Technology to Boost UK Manufacturing Productivity

Following the release of The Manufacturer and Barclays’ new report, Mind the Gap: Closing the Productivity Divide in the UK’s Manufacturing Sector, local surface finishing specialist Midland Deburr & Finish is supports highlighting the vital role that SMEs in precision finishing and component preparation play in closing the UK’s manufacturing productivity gap.

The report reveals that UK manufacturing productivity currently sits around 10% below the G7 average, with Germany 16% ahead in output per hour. However, the study also paints an optimistic picture, showing that 53% of UK manufacturers are prioritising reskilling, upskilling, and digital transformation to improve efficiency and competitiveness.

For Midland Deburr & Finish, which provides vibratory deburring, solvent degreasing, and vapour degreasing services, the findings echo the company’s own ongoing commitment to continuous improvement and technical investment.

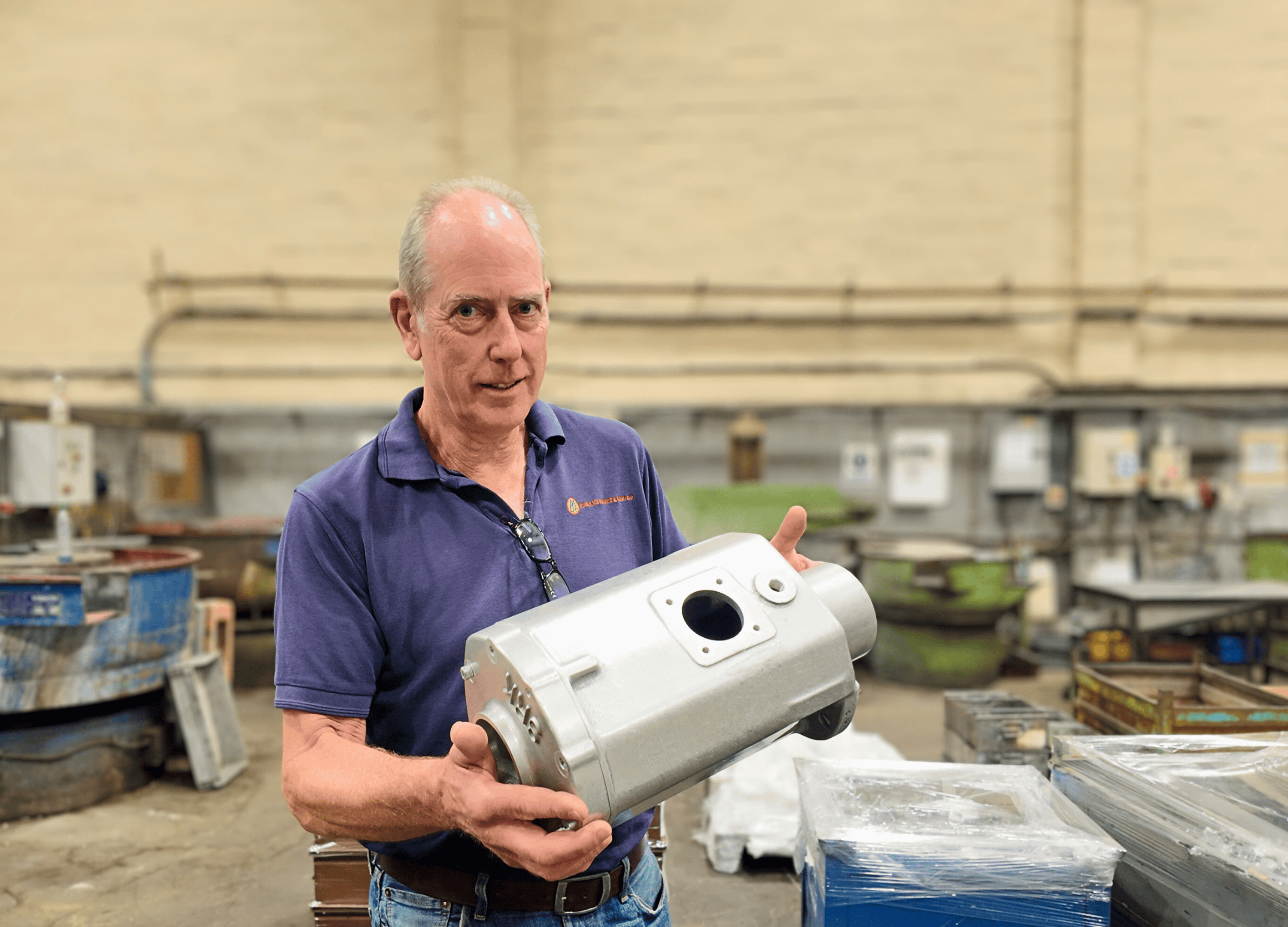

“Productivity and precision go hand in hand,” said Chris Arrowsmith, Managing Director at Midland Deburr & Finish. “When you’re working to exacting surface finish standards, efficiency means delivering consistently high-quality results, first time, every time. That’s why we’re investing in modern equipment, data-led processes, and training our team to operate at the cutting edge of finishing technology.”

Arrowsmith added that digital tools and process control are becoming increasingly important, even in traditionally hands-on disciplines such as surface finishing.

“We’re adopting digital monitoring and traceability systems within our workflow,” he explained. “From vibratory bowl performance to solvent quality tracking, we’re using data to ensure repeatability and reduce downtime. It’s a small-scale reflection of the digital transformation taking place across UK manufacturing.”

The Mind the Gap report also noted that over half of manufacturers (56%) believe national productivity is in decline, yet half (50%) are prioritising digital transformation in the next year. Encouragingly, 53% now use KPI dashboards for real-time tracking, and 42% have implemented ERP systems to enhance efficiency.

Arrowsmith believes that the momentum across the sector represents a turning point.

“There’s a real appetite among manufacturers, large and small, to modernise,” he said. “What’s crucial now is ensuring SMEs have the access and support they need—whether that’s through funding, training initiatives, or knowledge sharing—to make those changes meaningful. Surface finishing may be the last stage in the manufacturing process, but it’s one of the most important when it comes to product quality and customer satisfaction.”

As UK industry continues to navigate economic pressures and evolving customer demands, Midland Deburr & Finish remains focused on advancing its processes and workforce skills to deliver reliable, cost-effective finishing services for the manufacturing supply chain.

“We’re proud to be part of a sector that’s constantly improving,” concluded Arrowsmith. “By combining hands-on expertise with digital tools, we can help close the productivity gap from the ground up—ensuring UK manufacturing remains competitive on the global stage.”

Quick Contact Form