From Press Shop to Production Line: Fixing the Bottleneck Nobody Own

In many UK factories, the press shop hums efficiently, parts stack neatly on pallets, and production targets look achievable—right up until components reach assembly. It is here, between forming and final build, that a persistent bottleneck quietly undermines throughput: finishing.

Metal components may leave the press on time, but burrs, residual oils, and surface contamination can stall everything that follows. Deburring and cleaning are still too often treated as secondary processes—important, but not urgent—until quality issues, rework, or line stoppages force the issue.

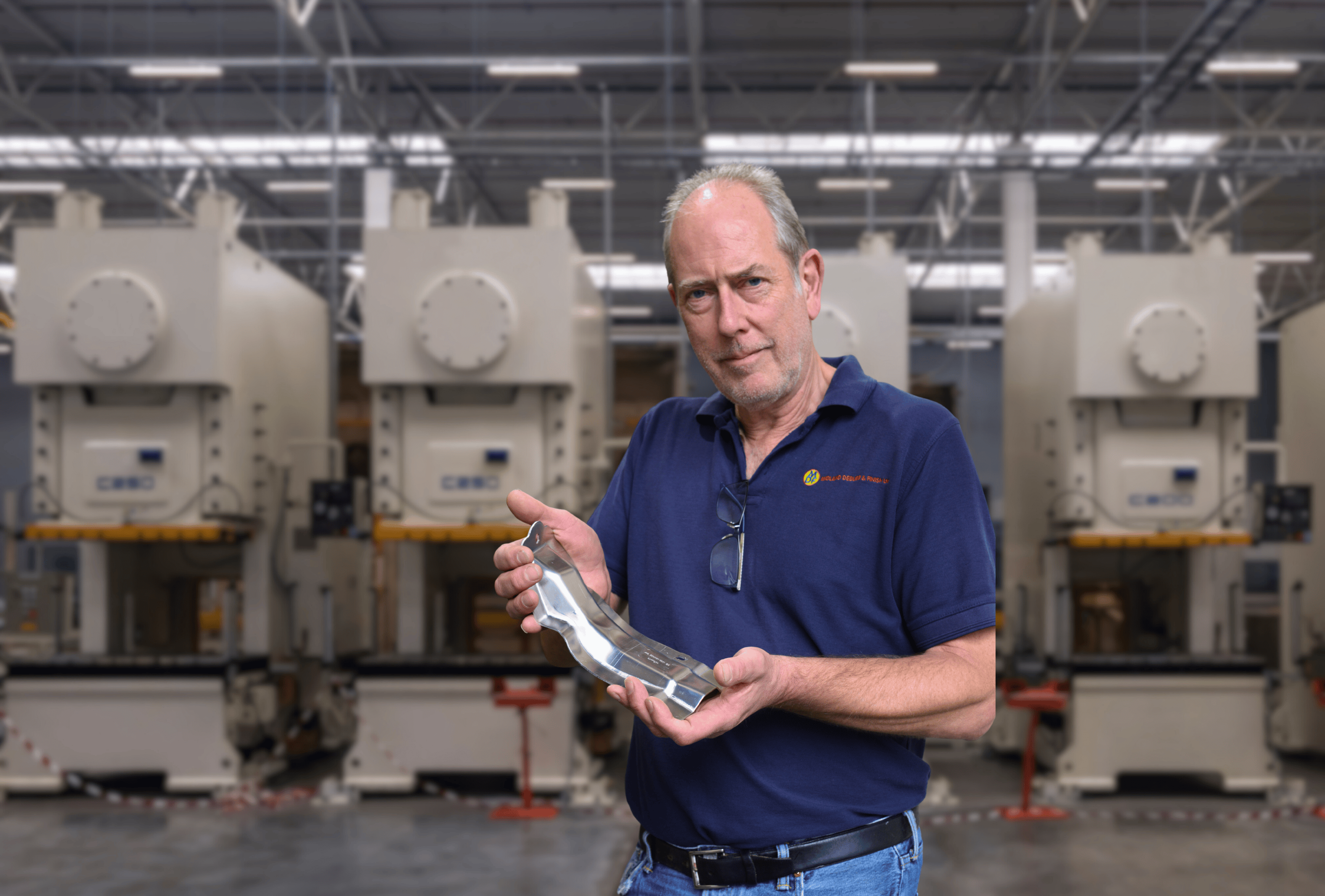

“Stamping and machining get the attention because they’re visible and capital-intensive,” says Chris Arrowsmith, Managing Director of Midland Deburr & Finish. “But if parts arrive at assembly with sharp edges or trapped contaminants, the problem doesn’t disappear—it just gets pushed further down the line, where it’s more expensive to fix.”

The finishing gap

For manufacturers in automotive, aerospace, and general industrial sectors, the challenge is familiar. Pressed or stamped parts require metal stamping deburring to remove sharp edges and prevent downstream damage, followed by stamping degreasing to eliminate oils that interfere with bonding, coating, or inspection.

When these steps are handled inconsistently—or squeezed into already stretched in-house capacity—the result is unpredictable flow. Assembly teams slow down, reject rates rise, and production planners lose confidence in lead times.

“Finishing becomes the bottleneck nobody owns,” Arrowsmith explains. “It sits between departments, so it doesn’t always have a clear champion. Yet it has a direct impact on quality, safety, and delivery performance.”

Cleanliness as a production requirement

The issue is particularly acute in regulated environments. In aerospace, aerospace component degreasing and controlled component cleaning are essential not just for performance, but for compliance and traceability. In automotive, automotive component degreasing ensures consistency in high-volume assembly and reduces the risk of warranty issues linked to contamination.

What unites these sectors is a growing recognition that finishing is no longer a cosmetic step—it is a production requirement.

“We’re seeing more customers come to us not because they lack equipment, but because they lack resilience,” says Arrowsmith. “Outsourcing specialist metal deburring and metal stamping deburring gives them predictable outcomes and frees up internal teams to focus on core processes.”

From constraint to capability

Specialist finishing providers are increasingly being used as an extension of the press shop rather than a corrective measure at the end of the line. By integrating deburring and degreasing earlier in the production plan, manufacturers can smooth flow, reduce work-in-progress, and protect assembly capacity.

“There’s a mindset shift happening,” Arrowsmith notes. “Finishing used to be about fixing problems. Now it’s about preventing them. When deburring and cleaning are done properly and at the right stage, everything downstream runs better.”

Quick Contact Form