Metal Deburring Steps Back Into the Spotlight as UK Manufacturers Focus on Quality, Safety and Long-Term Value

As UK manufacturers prepare for renewed investment driven by industrial strategy, digitalisation and export growth, one essential but often under-appreciated process is regaining attention: metal deburring and component cleaning.

While speed, precision and automation dominate much of the modern manufacturing conversation, industry specialists warn that overlooking finishing processes such as metal stamping deburring, component cleaning, and specialist degreasing can undermine quality, safety and long-term competitiveness.

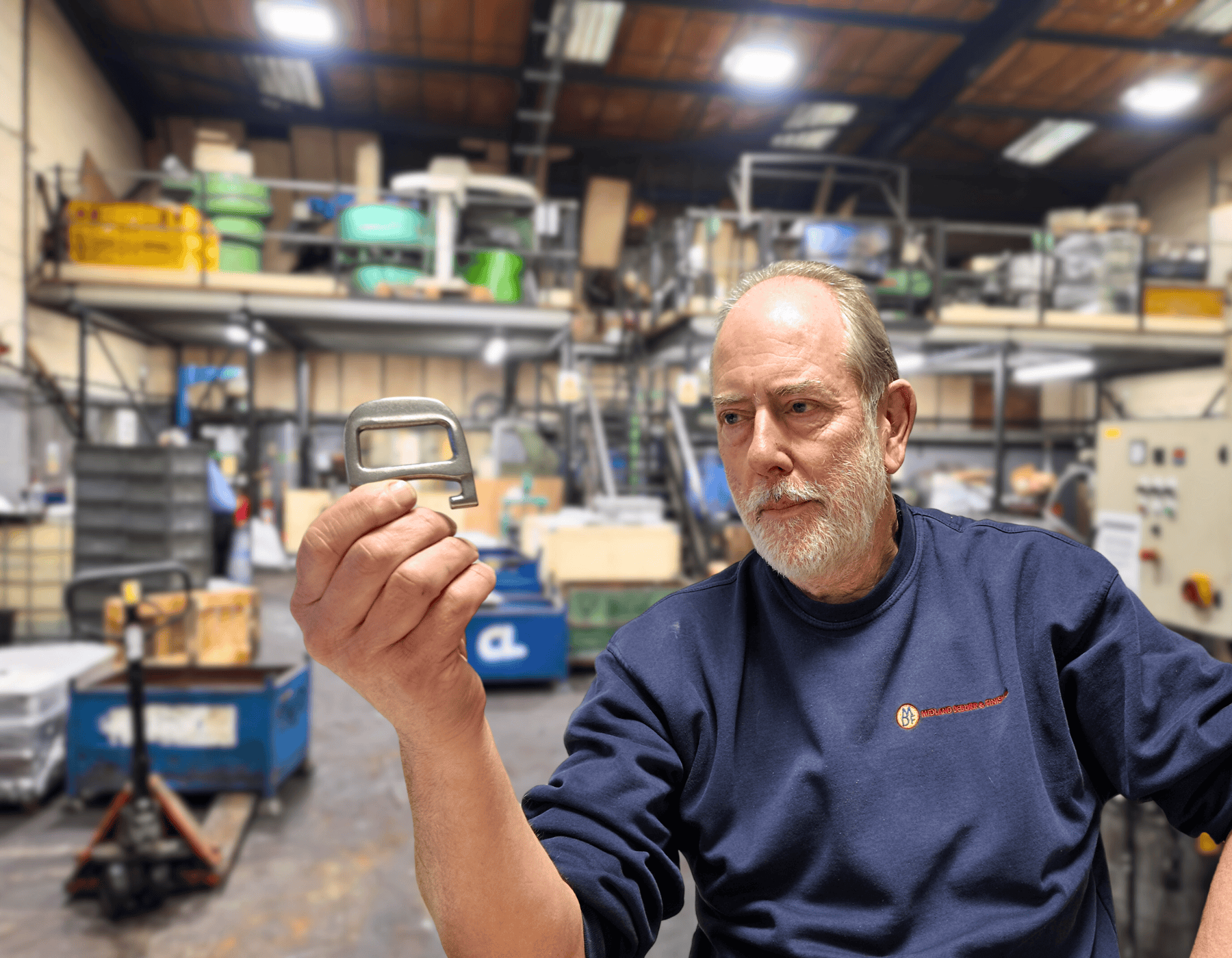

At Midland Deburr & Finish, Managing Director Chris Arrowsmith says the renewed focus on quality-led growth across UK manufacturing is long overdue.

“There’s a growing recognition that metal deburring is a fundamental part of making parts fit for purpose,” Arrowsmith explains. “As manufacturers invest in new products, automation and exports, edge quality and cleanliness become absolutely critical.”

Deburring as a Competitive Advantage

Recent industry surveys point to optimism for UK manufacturing in 2026, with companies prioritising new product development, digital technologies and expanded export markets. However, rising cost pressures are forcing manufacturers to scrutinise waste, rework and downstream inefficiencies more closely.

According to Arrowsmith, inadequate deburring and cleaning often sit quietly at the root of those hidden costs.

“A small burr can cause big problems – from assembly delays and coating failures to safety risks on the shop floor,” he says. “When margins are tight, avoiding rework and rejected components is just as important as investing in new machinery.”

From Metal Stamping to Final Assembly

For high-volume manufacturers, particularly those using presswork, metal stamping degreasing and metal stamping deburring play a crucial role in ensuring parts move smoothly into downstream processes.

Residual oils, sharp edges and microscopic burrs can interfere with automated assembly, fastening and finishing operations. In sectors such as automotive, where tolerances are tight and volumes are high, automotive component degreasing combined with consistent deburring helps maintain throughput while reducing manual intervention.

“Stamping oils left on parts can compromise coatings and bonding later on,” Arrowsmith notes. “Proper component cleaning early in the process protects everything that follows.”

Aerospace and Safety-Critical Demands

The stakes are even higher in regulated, safety-critical industries. Aerospace component degreasing and controlled deburring are essential to prevent stress concentrations, corrosion initiation and coating defects.

Smooth, radiused edges allow finishes to adhere evenly and reduce the risk of fatigue cracking over long service lives.

“In aerospace especially, you’re preparing components for decades of performance,” says Arrowsmith. “Deburring and cleaning directly influence durability, inspection outcomes and compliance.”

Quality, Reputation and Workforce Safety

Beyond technical performance, deburring also has a direct impact on workforce safety and brand reputation. Sharp edges remain a common cause of cuts, glove snags and handling injuries, while poorly finished components can signal low quality to customers – even when dimensional tolerances are met.

“Manufacturers talk a lot about productivity, so a safer part is also a more productive part,” Arrowsmith adds. “Well-deburred components reduce injury risk, improve handling and reflect a level of professionalism customers expect.”

Finishing Processes in a Growth-Focused Manufacturing Sector

As UK manufacturers balance optimism with rising costs, attention is shifting toward processes that protect value rather than simply add speed. With increased focus on automation, export readiness and quality assurance, deburring and degreasing are moving from the background to the boardroom agenda.

“If you’re investing in innovation and growth, it makes no sense to let poor edge quality undermine that investment,” Arrowsmith concludes. “Deburring is about making manufacturing work better, end to end.”

For companies navigating the next phase of UK manufacturing growth, the message is clear: clean, safe and consistently finished components are no longer optional – they are a foundation for competitiveness in a demanding global market.

Quick Contact Form