Midland Deburr & Finish Secures Major Orders for Solvent & Vapour Degreasing Automotive Work

Lye-based finishing specialist Midland Deburr & Finish Ltd has announced a significant contracts milestone, having secured major orders for its advanced solvent and vapour degreasing plant to support tier one automotive component work for a leading UK-based OEM.

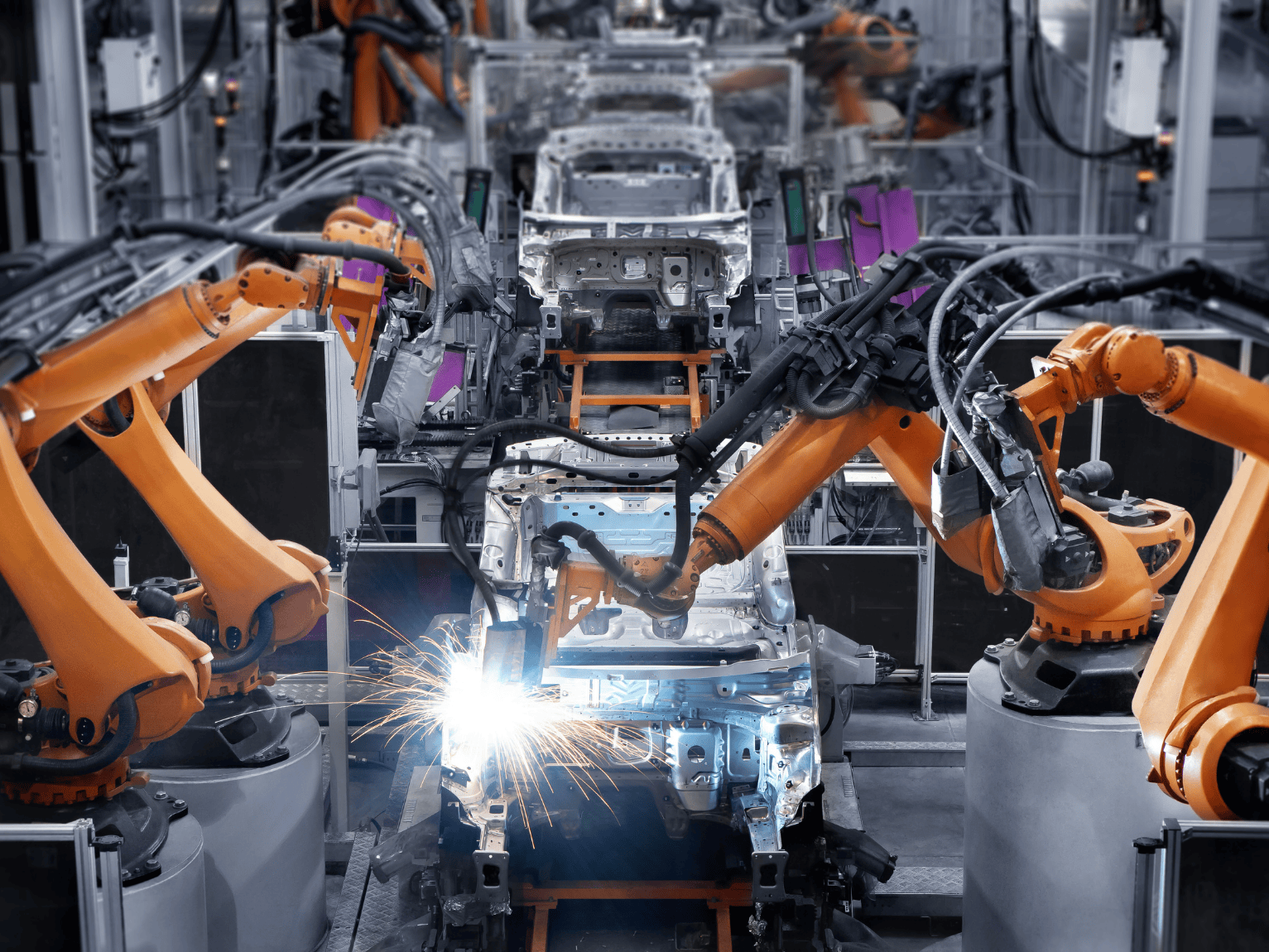

As modern manufacturing becomes increasingly complex, precision finishing processes like deburring and degreasing are more essential than ever. These operations are vital to ensuring components meet stringent performance, safety, and reliability standards. Yet, with high investment costs and a deepening industry-wide skills gap, many manufacturers are turning to outsourced solutions to meet these needs.

Midland Deburr & Finish is playing a pivotal role in helping manufacturers stay ahead of these demands. Managing Director Chris Arrowsmith confirmed the company’s new orders mark a significant vote of confidence in their capabilities and long-standing expertise.

“We’re proud to be supporting tier one and tier two automotive supply chains with our solvent and vapour degreasing technologies,” said Arrowsmith. “These orders reflect the trust major OEMs place in our ability to deliver precision and consistency at scale.”

The investment will support the firm’s growing role in the UK automotive sector, where components must adhere to the highest standards of cleanliness and finish. Vapour and solvent degreasing are critical processes in this space, removing minute contaminants that can compromise the performance or durability of parts—particularly those used in engines, transmission systems, and braking components.

The complexity of precision finishing often places a heavy burden on manufacturers. The capital outlay required for specialist equipment, combined with the challenge of sourcing and retaining skilled operators, has made outsourcing an increasingly attractive option.

“These processes are essential in modern manufacturing,” Arrowsmith noted. “But they require significant expertise, and that’s where we step in—so our customers don’t have to divert their resources away from their core operations.”

By offering a comprehensive subcontract solution, Midland Deburr & Finish enables manufacturers to focus on core production without sacrificing quality. The company’s Lye-based operation offers a full spectrum of finishing services, from vibratory and centrifugal deburring to the highly specialised solvent and vapour degreasing now at the centre of its latest contracts.

The firm’s reputation has been built on the integration of advanced technologies with traditional know-how. Whether it’s handling intricate components from additive manufacturing or ensuring surface readiness for critical assemblies, Midland Deburr & Finish approaches every part with the same commitment to excellence.

These latest contracts further underscore Midland Deburr & Finish’s position as a trusted partner in high-precision manufacturing sectors. Their Lye facility operates with strict quality controls and offers logistical support, including pickup and delivery, to ensure seamless integration into clients’ production cycles.

“We want manufacturers to see firsthand the difference expert finishing makes,” Arrowsmith added. “Every detail matters to us, from preventing impingement damage to ensuring the most efficient drainage systems. It’s about delivering excellence every time.”

As manufacturers continue to pursue innovation while managing cost pressures and skill shortages, outsourcing specialist services like finishing becomes not just a tactical choice, but a strategic one. Midland Deburr & Finish is leading this transition by offering the reliability, capacity, and expertise that tier one suppliers and OEMs require.

“At Midland Deburr & Finish, we believe that attention to detail has the greatest impact,” Arrowsmith concluded. “Our mission is to ensure that every component we handle meets the highest standards of quality and performance, allowing our clients to focus on what they do best—manufacturing excellence.”

With over 25 years of industry experience and a growing footprint in automotive manufacturing, Midland Deburr & Finish continues to transform finishing challenges into strategic advantages for its clients—one component at a time.

Quick Contact Form