Midland Deburr & Finish Supports UK’s EV Surge with Precision Finishing Expertise

As the UK government reignites support for electric vehicle (EV) adoption with new grants and infrastructure funding, Midland Deburr & Finish Ltd is stepping up to play a vital role in ensuring the performance and reliability of critical EV components.

The return of the electric car grant—announced this week for the first time since 2022—is a welcome development for the automotive industry. Backed by £63 million in additional chargepoint funding, the scheme is designed to accelerate the UK’s transition to electric mobility. For companies like Midland Deburr & Finish, based in Lye, this momentum represents not only an industry milestone but a growing opportunity to support EV supply chains with specialist deburring and degreasing services.

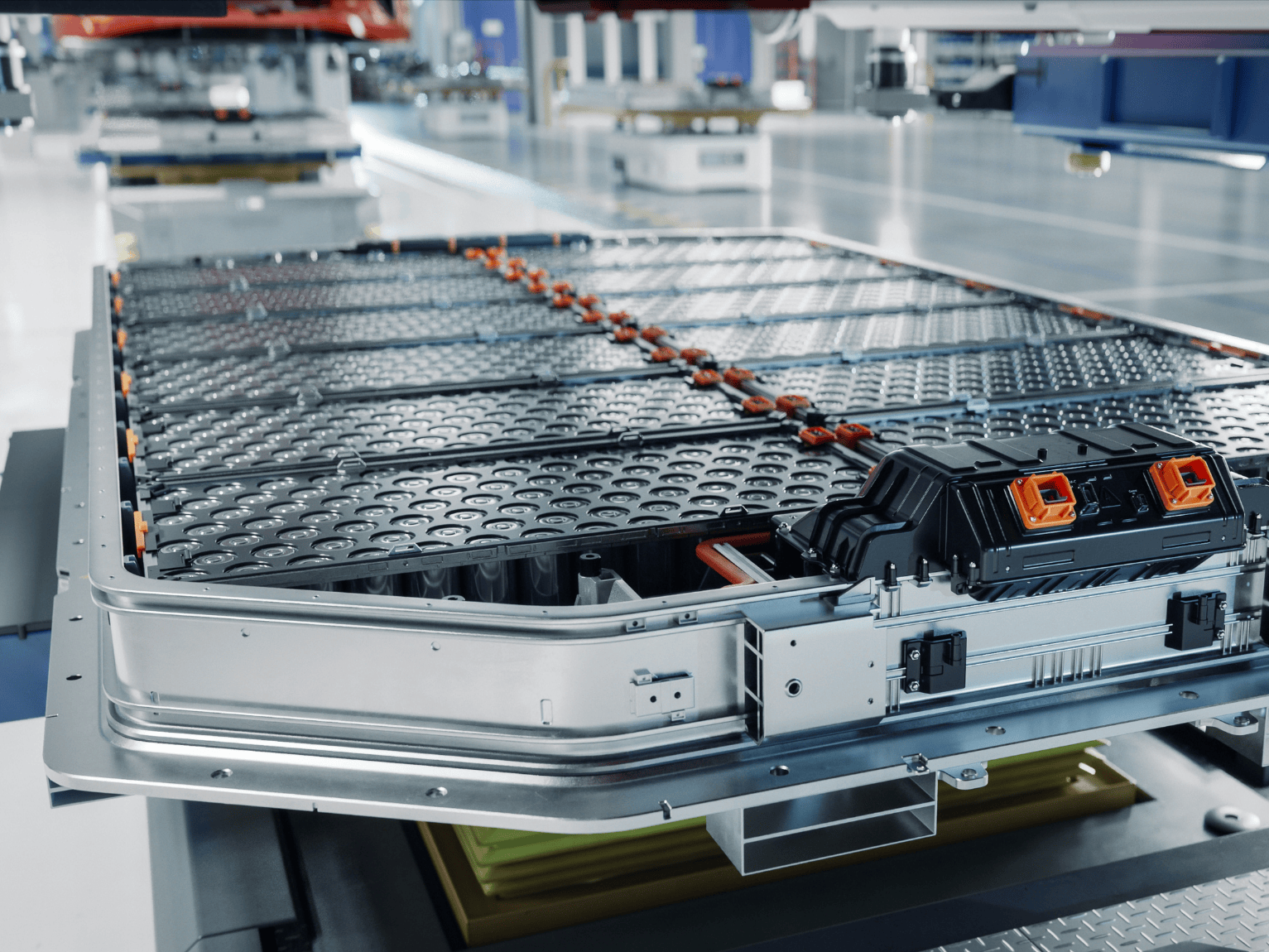

As EV adoption increases, so does the need for extreme precision in the production and finishing of the components that power these vehicles. From battery casings and cooling system parts to electric motor housings and high-voltage connectors, the quality and cleanliness of every part directly impacts vehicle performance, safety, and durability.

“EV components are often made from lightweight, high-performance materials and complex geometries that demand meticulous finishing,” explains Chris Arrowsmith, Managing Director of Midland Deburr & Finish. “Our deburring and degreasing processes are essential to prepare these parts for optimal performance, whether it's removing burrs that could cause mechanical failures or eliminating residues that interfere with thermal management systems or electronic conductivity.”

With over 25 years of experience, Midland Deburr & Finish has become a trusted finishing partner across the UK’s advanced manufacturing landscape. As the electric vehicle market expands, the company is seeing increasing demand from component manufacturers looking to meet rigorous industry standards without the overheads of in-house finishing.

“Our customers are under pressure to scale up quickly while meeting exacting OEM specifications,” Arrowsmith adds. “By outsourcing their finishing to us, they can accelerate production timelines and avoid costly investment in equipment and training.”

According to the Society of Motor Manufacturers and Traders (SMMT), only one in four new vehicles sold in the UK today is electric—but that number is expected to rise to four in five by the end of the decade. With more than 130 electric models now on the market and increasing affordability, demand for components is set to rise exponentially.

To help meet this challenge, Midland Deburr & Finish has refined its finishing techniques to serve EV manufacturers with speed, scalability, and repeatable quality. The company’s Lye-based facility is equipped with advanced vibratory, centrifugal, solvent, and vapour degreasing technology—capable of handling everything from small, delicate sensor housings to large structural parts.

“We understand the critical nature of EV components, and we treat every part with that level of importance,” says Arrowsmith. “It’s crucial ensuring the part functions flawlessly for years to come.”

The government’s recent EV grant, paired with £2.5 billion in support through the DRIVE35 Automotive Transformation Fund, underscores a national commitment to decarbonisation and industrial growth. For Midland Deburr & Finish, it’s a validation of the work they’ve been doing behind the scenes—helping manufacturers overcome challenges related to precision finishing as the industry evolves.

“This is a turning point for the UK’s automotive sector,” Arrowsmith concludes. “As the country moves toward net zero, we’re proud to support the shift to electric by making sure every component meets the highest standards of cleanliness, reliability, and performance. The EV future in this country is now around execution, and that’s where we come in.”

As the UK’s EV market accelerates, companies like Midland Deburr & Finish will remain essential partners in delivering the quality and consistency needed to keep electric mobility running smoothly—one component at a time.

Quick Contact Form