Midland Deburr & Finish Welcomes UK Government’s Backing of Ford’s EV Transition

A key player in the UK’s precision surface finishing sector, Midland Deburr & Finish, has publicly welcomed the Government’s recent announcement of a £1 billion export development guarantee to Ford UK, calling it a landmark moment for British manufacturing and a powerful vote of confidence in the country’s transition to electric vehicles (EVs).

The government-backed loan—guaranteed by UK Export Finance (UKEF)—will support Ford’s continued development of electric motors, cleaner engines, and export-ready automotive technologies. As a critical supplier within the UK automotive supply chain, Midland Deburr sees the investment as both a national economic stimulus and an industry-wide opportunity.

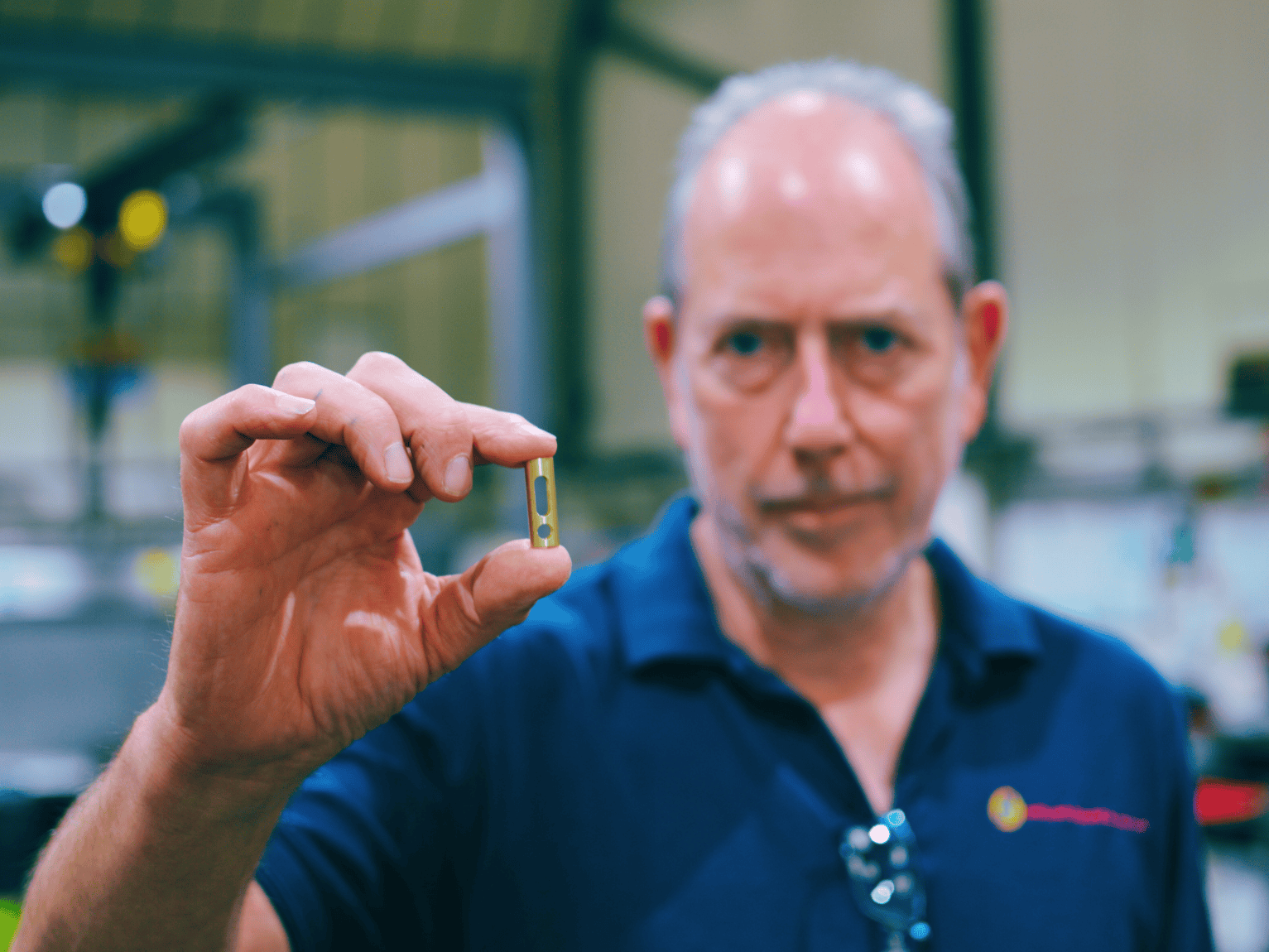

Chris Arrowsmith, Managing Director of Midland Deburr & Finish, praised the announcement:

“Ford has been at the heart of British automotive engineering for more than a century. This new financial support is not just a lifeline for one of our most iconic manufacturers—it’s a clear signal that the UK is serious about competing in the global electric vehicle race. At Midland Deburr, we are proud to play a supporting role in this transition by delivering high-spec finishing and degreasing services for automotive and EV components alike.”

Midland Deburr & Finish, headquartered in Lye, West Midlands, provides advanced solvent and vapour degreasing services, along with precision deburring of a wide range of metal components. Its work spans conventional and electric vehicle parts, including complex engine housings, battery components, and precision gears supplied to Tier 1 and OEM clients.

Arrowsmith added; “This kind of government intervention recognises the deep interconnectivity of the UK’s manufacturing base. For every electric motor Ford produces in Halewood, there are dozens of UK-based suppliers—like ourselves—ensuring those components are production-ready. Supporting Ford is supporting an entire ecosystem of high-skill, high-tech jobs across the UK.”

Ford’s investment in electrification includes a £380 million transformation of its Halewood plant and £70 million in advanced R&D facilities in Essex. The company’s export-driven growth strategy is now further bolstered by the UKEF facility, part of the government’s broader Plan for Change and Modern Industrial Strategy, which aims to accelerate clean growth, support high-value jobs, and secure Britain’s place in the next generation of automotive innovation.

With the automotive sector accounting for £67 billion of turnover and employing over 180,000 people in the UK, companies like Midland Deburr are increasingly vital to meeting demand for clean, export-ready components.

“We welcome any strategy that helps unlocking the UK’s manufacturing potential,” said Arrowsmith. “We’re already supporting EV component manufacturers, and this kind of strategic investment allows SMEs like ours to continue innovating and contributing to the UK’s global competitiveness.”

As the UK strengthens its export capabilities and EV credentials, Midland Deburr & Finish plans to expand its capabilities in both degreasing and finishing for advanced materials, ensuring it remains a valuable partner in the evolving automotive landscape.

Quick Contact Form