Midland Deburr Wins Horticultural Orders Evidencing UK Manufacturing’s Resilience Amidst Troubling Report

A new report has suggested that UK manufacturing is “falling behind” international competitors in automation and digital adoption. Yet firms on the ground are telling a different story — one of agility, innovation, and resilience.

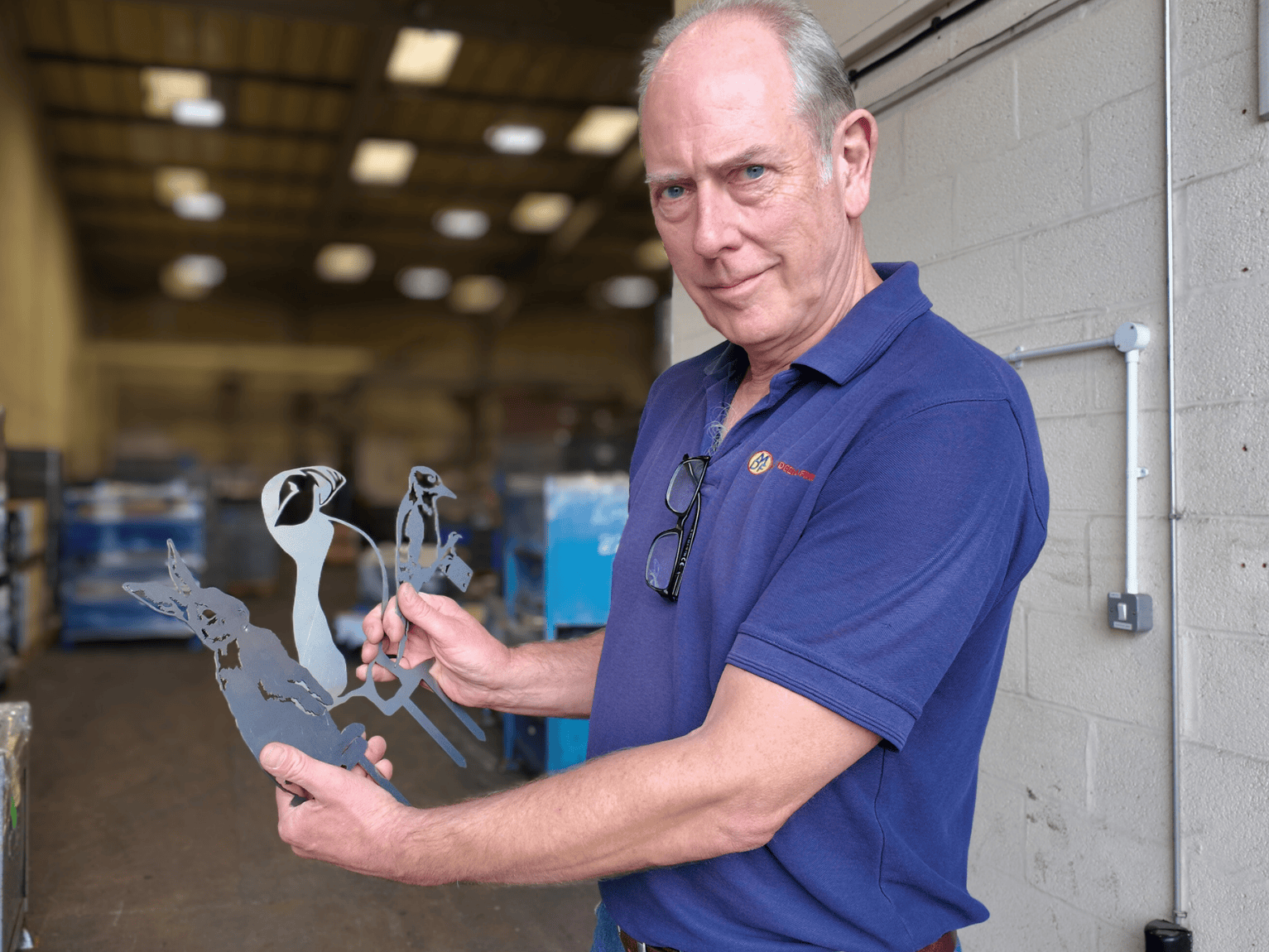

Midland Deburr & Finish, a Lye-based specialist in deburring, metal degreasing, solvent degreasing and vapour degreasing, is a case in point. Known for its precision finishing services to aerospace and automotive supply chains, the company has recently secured a series of orders in an entirely new market: ornamental garden stakes.

For Managing Director Chris Arrowsmith, this diversification is not just about finding new revenue streams — it’s about proving how responsive UK manufacturers can be to changing demand.

“Winning contracts in ornamental garden stakes might sound like a departure from aerospace,” Arrowsmith said, “but the underlying requirement is the same: delivering high-quality, repeatable finishing at competitive costs. Our ability to apply advanced degreasing and deburring processes to a new sector shows exactly how agile British SMEs can be.”

The new contracts demonstrate the firm’s adaptability in deploying automated finishing techniques. Using solvent and vapour degreasing technologies originally refined for high-value aerospace components, Midland Deburr & Finish has been able to ensure corrosion resistance, smooth edges, and consistent finishes for large batches of decorative steel products.

Arrowsmith believes this kind of agility undermines the view that UK manufacturing lags behind global rivals due to a lack of appetite for innovation.

“The will is there — we’re proving it every day,” he said. “The challenge isn’t that firms like ours don’t want to automate or adopt smarter processes. It’s that support structures are fragmented, making investment decisions harder than they should be. Despite that, we’re still competitive, and that’s a real credit to the resilience of the sector.”

The Make UK/Sage report released this week compared the UK unfavourably with countries such as South Korea, Singapore and Switzerland, pointing to long-term national strategies that make funding and skills support simple to access. While Arrowsmith acknowledges these examples are valuable, he insists UK manufacturing’s ability to pivot — from supplying aerospace engine components one month to garden stakes the next — is a strength that should not be overlooked.

“That adaptability is what keeps us in the game,” he added. “It’s not about whether UK firms are willing to innovate — it’s about ensuring we have the same long-term framework as our international competitors. Give us that, and the agility you see in SMEs like ours will translate into even greater competitiveness.”

With demand in both traditional aerospace and new consumer-facing markets, Midland Deburr & Finish shows that UK manufacturers are not standing still. Far from falling behind, the sector is demonstrating the versatility and determination that have long underpinned its global reputation.

Quick Contact Form