Midland Deburr & Finish agility pays off for vibratory deburring and metal degreasing services orders

From tiny machined components to heavy castings the size of an engine block, Midland Deburr & Finish Ltd, based in Lye, is seeing an extraordinary breadth of parts arriving at its facility for specialist cleaning, vibratory deburring, and metal degreasing.

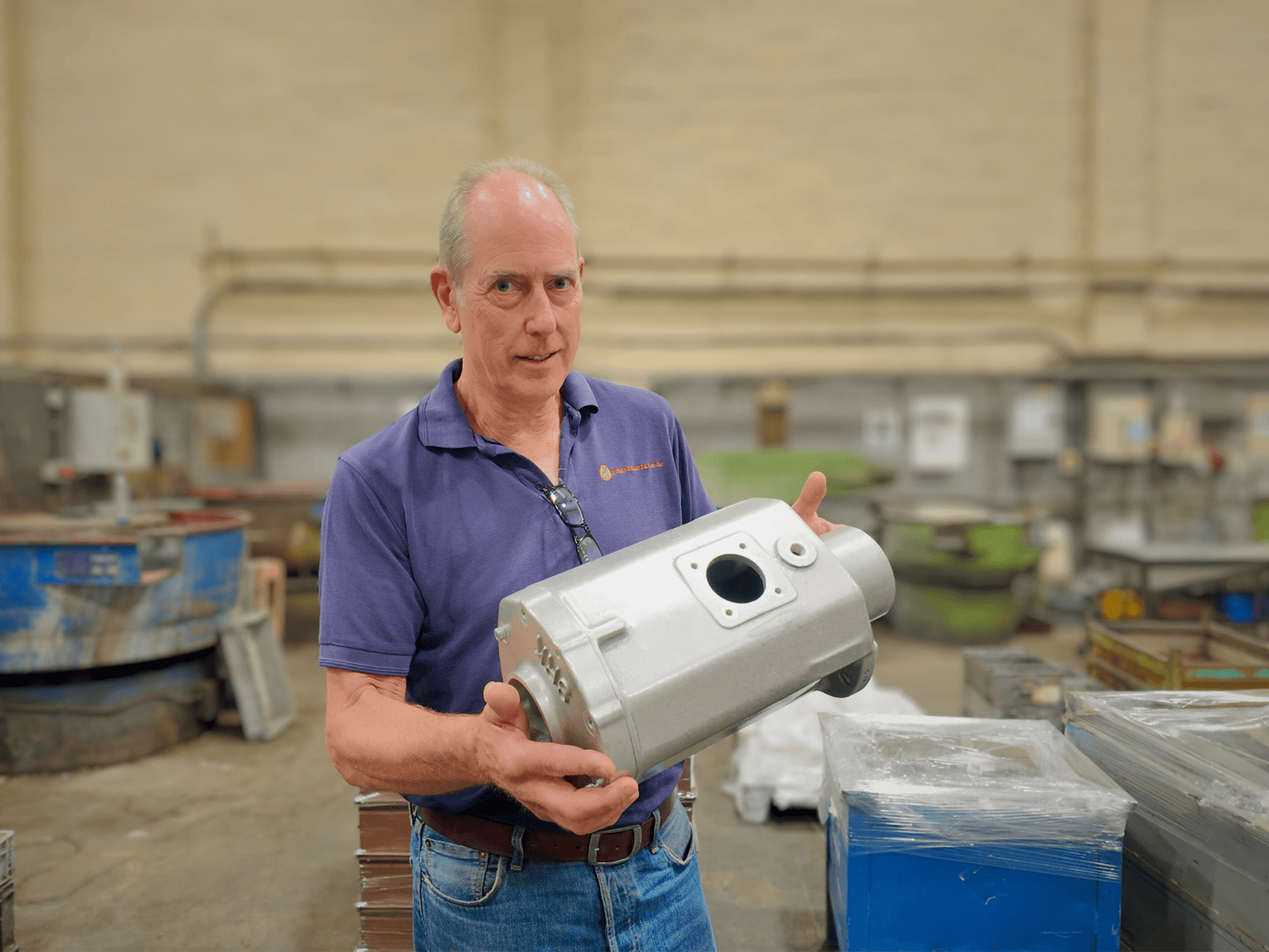

Managing Director Chris Arrowsmith, pictured holding a large cast part recently processed through the company’s state-of-the-art solvent degreasing plant, says the growth reflects both the pressures and opportunities facing UK manufacturers.

“Customers are under more pressure than ever to deliver flawless components,” Arrowsmith explained. “We’re seeing everything from aerospace rings and precision pressings to huge castings coming through our doors. The common factor is the need for absolute consistency – whether that’s through vibratory deburring to achieve the perfect surface finish, or vapour degreasing to ensure every trace of oil and contamination is removed.”

Midland Deburr & Finish offers one of the Midlands’ most comprehensive finishing services, combining vibro-polishing, vibratory deburring, and metal degreasing with next-day turnaround, free local delivery, and batch flexibility ranging from single components to thousands. Its expertise spans ferrous, non-ferrous and plastic parts – serving customers across the automotive, aerospace, energy and general engineering supply chains.

The rise in parts being sent for degreasing and deburring reflects the increasing standards demanded by OEMs and Tier 1 suppliers. Proper finishing delivers not just cosmetic improvements, but also better performance and safety. Vibratory deburring removes sharp edges and burrs, preventing wear on adjacent parts and reducing fatigue failures.

Metal degreasing through solvent degreasing and vapour degreasing ensures flawless cleanliness, critical before plating, painting or assembly. Unlike aqueous processes, vapour degreasing leaves no watermarks or stains – ensuring a pristine finish every time.

“There’s a misconception that deburring is just about appearance,” Arrowsmith added. “In reality, it’s about reliability, safety and performance. Burrs can create stress points that cause fatigue, or lead to premature wear when parts interact. Likewise, poor cleaning can compromise coating adhesion or allow contaminants to creep into assemblies. That’s why more and more customers are turning to us.”

The Lye facility is equipped with a wide range of vibratory bowls, a comprehensive library of compounds and media, and advanced metal degreasing machines capable of handling components from just 2mm up to 1.5 metres. The firm’s ISO 9001 and ISO 14001 approvals underline its commitment to quality and environmental standards.

As Arrowsmith points out, the mix of work keeps the team on its toes:

“One morning we could be processing thousands of tiny machined parts for the automotive sector; in the afternoon, a single large aerospace casting requiring precision vapour degreasing. That variety is what makes our work so rewarding – and it shows just how vital finishing has become across modern manufacturing.” With UK industry under pressure to deliver world-class performance at every stage of the supply chain, Midland Deburr & Finish’s message is clear: quality finishing isn’t an afterthought, but a vital link in the chain of advanced manufacturing.

Managing Director Chris Arrowsmith, pictured holding a large cast part recently processed through the company’s state-of-the-art solvent degreasing plant, says the growth reflects both the pressures and opportunities facing UK manufacturers.

“Customers are under more pressure than ever to deliver flawless components,” Arrowsmith explained. “We’re seeing everything from aerospace rings and precision pressings to huge castings coming through our doors. The common factor is the need for absolute consistency – whether that’s through vibratory deburring to achieve the perfect surface finish, or vapour degreasing to ensure every trace of oil and contamination is removed.”

Midland Deburr & Finish offers one of the Midlands’ most comprehensive finishing services, combining vibro-polishing, vibratory deburring, and metal degreasing with next-day turnaround, free local delivery, and batch flexibility ranging from single components to thousands. Its expertise spans ferrous, non-ferrous and plastic parts – serving customers across the automotive, aerospace, energy and general engineering supply chains.

The rise in parts being sent for degreasing and deburring reflects the increasing standards demanded by OEMs and Tier 1 suppliers. Proper finishing delivers not just cosmetic improvements, but also better performance and safety. Vibratory deburring removes sharp edges and burrs, preventing wear on adjacent parts and reducing fatigue failures.

Metal degreasing through solvent degreasing and vapour degreasing ensures flawless cleanliness, critical before plating, painting or assembly. Unlike aqueous processes, vapour degreasing leaves no watermarks or stains – ensuring a pristine finish every time.

“There’s a misconception that deburring is just about appearance,” Arrowsmith added. “In reality, it’s about reliability, safety and performance. Burrs can create stress points that cause fatigue, or lead to premature wear when parts interact. Likewise, poor cleaning can compromise coating adhesion or allow contaminants to creep into assemblies. That’s why more and more customers are turning to us.”

The Lye facility is equipped with a wide range of vibratory bowls, a comprehensive library of compounds and media, and advanced metal degreasing machines capable of handling components from just 2mm up to 1.5 metres. The firm’s ISO 9001 and ISO 14001 approvals underline its commitment to quality and environmental standards.

As Arrowsmith points out, the mix of work keeps the team on its toes:

“One morning we could be processing thousands of tiny machined parts for the automotive sector; in the afternoon, a single large aerospace casting requiring precision vapour degreasing. That variety is what makes our work so rewarding – and it shows just how vital finishing has become across modern manufacturing.” With UK industry under pressure to deliver world-class performance at every stage of the supply chain, Midland Deburr & Finish’s message is clear: quality finishing isn’t an afterthought, but a vital link in the chain of advanced manufacturing.

Quick Contact Form