Precision Finishing Firm Welcomes Signs of Recovery in UK Automotive Sector

The latest figures from the Society of Motor Manufacturers and Traders (SMMT) offer a glimmer of optimism for Britain’s embattled automotive sector. Car output rose for the second consecutive month in July, with both domestic and overseas demand showing momentum despite an uncertain global backdrop.

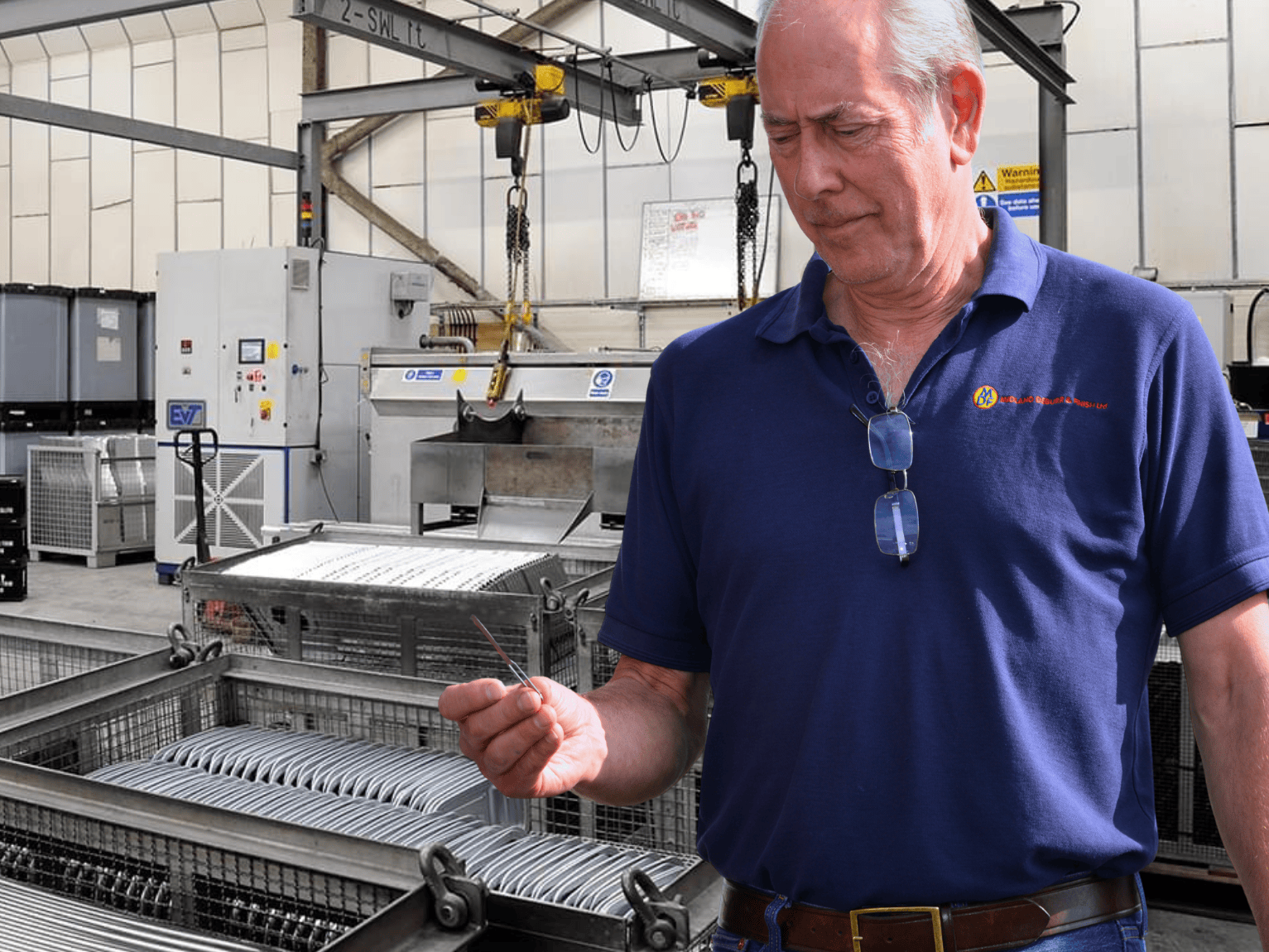

For suppliers in the Midlands—long considered the beating heart of UK automotive manufacturing—such data is a welcome tonic. Nowhere is this more keenly felt than in Lye, Stourbridge, where Midland Deburr & Finish continues to support Tier 1 and Tier 2 manufacturers with advanced component finishing services.

“Every uptick in vehicle production has a direct knock-on effect for us,” said Chris Arrowsmith, Managing Director of Midland Deburr & Finish. “When OEMs and their supply chains are confident enough to invest in volume, they need partners like us to guarantee quality, repeatability and compliance in every finished component. That’s where processes like vibratory deburring, vapour degreasing and solvent degreasing come into their own.”

The company specialises in vibratory deburring, a technique that smooths sharp edges and burrs from machined or stamped components, ensuring parts are both safe and reliable in demanding automotive applications. The process is highly scalable, enabling bulk finishing of complex geometries to consistent tolerances.

Complementing this, vapour degreasing and solvent degreasing play a crucial role in preparing components for downstream assembly and surface treatment. These cleaning technologies remove oils, coolants and particulates, delivering pristine finishes that comply with stringent industry standards.

“Quality is only as good as the preparation behind it,” Arrowsmith explained. “Our customers trust us to finish their components, and to ensure every part that leaves our facility is production-line ready, cleanliness and precision matter more than ever.”

The SMMT data highlights both promise and pitfalls for the sector. While car output is on the rise—helped in part by transatlantic exports following the operationalisation of the UK-US trade deal—commercial vehicle production has slumped by more than 80% year-on-year, reflecting restructuring and exceptional performance in 2023.

Despite these headwinds, the outlook beyond 2026 appears brighter. New investments in plants and product lines are expected to fuel annual growth and underpin the UK automotive sector’s contribution to trade, employment, and the net zero transition.

For Arrowsmith, this longer-term trajectory underscores the importance of suppliers maintaining investment in skills, processes and people.

“The automotive sector is constantly evolving, and so are its demands,” he said. “That’s why we invest in state-of-the-art finishing technologies and in training and upskilling our team. A highly skilled workforce is the foundation of Britain’s competitiveness—and it’s vital for businesses like ours to play our part in that.”

As Britain’s automotive sector steadies itself for the next phase of growth, suppliers like Midland Deburr & Finish will continue to play a vital role in the supply chain’s resilience. By delivering precision finishing services at scale, the business ensures that UK-made vehicle are backed by quality, reliability and world-class standards.

“In this industry, recovery is never straightforward,” Arrowsmith concluded. “When we see production lines firing up again, it gives everyone in the supply chain a boost. We’re proud to be part of that story—and determined to keep delivering the standards that UK automotive is renowned for worldwide.”

Quick Contact Form